The phrase, “If it ain’t broke, don’t fix it” has been in use for generations. It may well suit some applications such as your home TV or your recreational surfboard but, in reference to modern machines and their maintenance, it is an antiquated expression.

Miners, Manufacturers and companies large and small are functioning in as competitive an economic environment as ever. Any advantage that can be garnered over rivals is sought out and is often used. That advantage over competitors practice must include investment in maintenance processes and in cases where applicable, a good vibration monitoring program.

The current economic climate in Australia means that any investments are being examined intensely before approvals are given. For any spending to go ahead a highly credible and persuasive case will need to be made to encourage those holding the purse strings to release the funds to initiate plans. Fortunately, predictive maintenance and vibration monitoring can be shown to pay for itself.

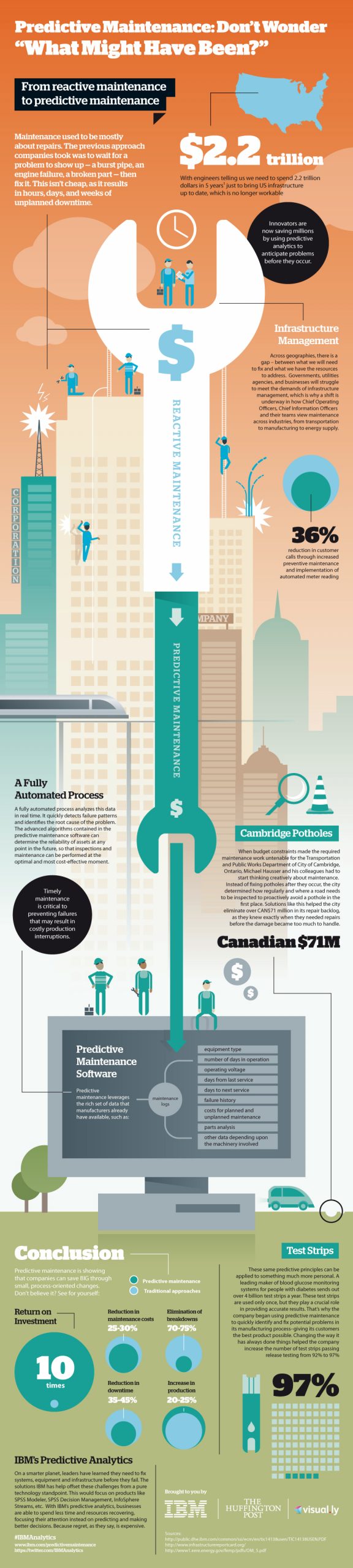

Analysis carried out by IBM showed that, when measured against traditional maintenance methodologies, predictive maintenance condensed expenses by 25-30%. Not only this but downtime was shown to be reduced by 35-40% and best of all; the ROI was 10 times higher than traditional maintenance strategies and approaches.

The size and expense for some of the machines where GVS Reliability Products (GVS) have customers install their vibration accelerometers is characteristically colossal. The reliance placed upon GVS vibration and oil analysis hardware to work efficiently to guarantee production and revenue targets are met is just as substantial.

So the question remaining is; “Why run a risk when it comes to maintenance”?

Perhaps the old adage “if it ain’t broke, don’t fix it” would be better phrased; “if it aint broke, find out when it might so you don’t have to fix it.” Or… something like that anyway…

The information for this blog was taken from the infographic below.

If you would like to learn more about vibration sensors, wireless vibration monitoring, oil sampling points or even just a chat about condition monitoring in general, please don’t hesitate to contact one of our sales team today.