GV-700 Vibe Port Wireless Vibration & Temperature Transmitter

OVERVIEW:

This paper is an application review of the GV-700 Vibe Port Wireless vibration & temperature transmitter (refer GV700 VIBE PORT FLYER for the unit’s technical specifications, available on request from GVS)

APPLICATION:

Wireless GV-700 Vibe Port was fitted to a shuttle pulley in a screen house, this critical to production shuttle pulley traversed across the screen house with the conveyor pulley rotating around 91 RPM. The system was set up and manual data was collected via condition monitoring personal on a routine basis. This pulley is critical to the throughput of the plant, and being in an awkward location (on top of the screen house), it is also critical due to the resources required to be arranged for a change out.

ANALYSIS:

The vibration data (on page two) clearly indicated a cracked inner raceway, plans were then put into place to change the pulley out. This included: – sourcing the third party lifting equipment and resources – writing the controlled safety plan to change out – scheduling the change out at the next planned maintenance slot …so as to not disrupt the production schedule.

Maximize Production – Minimize unnecessary Maintenance

VIBRATION DATA:

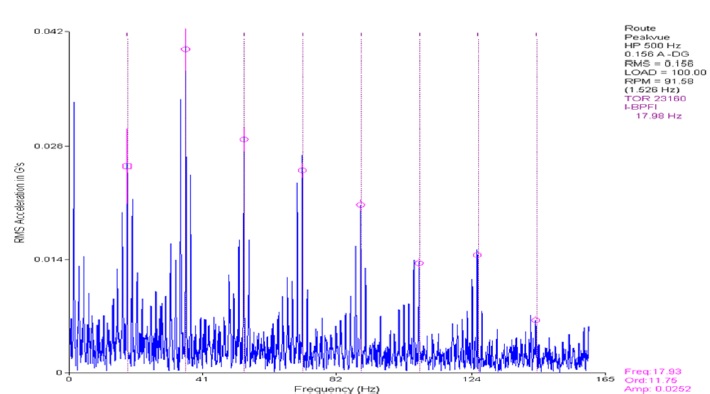

The PeakVue Acceleration spectrum displays a fundamental with harmonics that match the calculated defect frequency for the bearing inner raceway, this is also side banded by running speed harmonics.

VIBRATION DATA:

The PeakVue Acceleration time waveform displays a regular impact for each revolution of the shaft.

INSPECTION:

On dismantling of the conveyor pulley it was evident that the inner raceway had a through crack and had started to spin and pick up on the shaft.

Simplifying Wireless, No Software

SUMMARY:

The wireless GV-700 Vibe Port enabled detection of the failure of a bearing prior to catastrophic unplanned shutdown. It is estimated that if this had failed without prior knowledge this would have disrupted production schedule throughput by around 150,000 tonnes. This excludes extra costs involved with deploying contractors in a breakdown situation and the increased safety risk exposure in a breakdown situation.

GOOD VIBRATION SENSORS – contact GVS Sales Team TODAY to discuss your requirements