Why We Ignore Leaks

Compressed air is a misunderstood utility. As such, it tends to be misused and even abused. Leaks continue to be the biggest problem; often overlooked because they are difficult to detect, don’t smell bad, don’t make a mess on the floor, and rarely stop production.

The Real Cost of Leaks

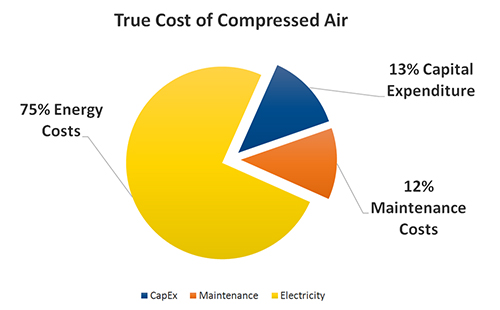

One of your factory’s highest operating expenses is the energy consumed by your compressed air system. Only 25% of the cost of a compressed air system is capital cost and maintenance. The remaining 75% is energy, and as much as 35% of that energy is wasted satisfying leaks.

Additional Impacts

Compressed air leaks create fluctuations in system pressure, which negatively impacts product quality. Compressors work overtime to compensate, leading to early degradation of the asset. Eventually, the compressor system can’t keep up with demand. What can you do? Buy yet another compressor for more capacity? Or optimize the capacity you already have by finding and fixing leaks?

With so much at stake, why are compressed air leaks managed so poorly, and why doesn’t every organization have an air leak management program?

Where to Look for Leaks

Every component has the potential to leak, but we can hasten our search by focusing on common failure points. Usual problem areas are branch line connections, automatic drain traps, desiccant filters, regulators, coalescent filter assemblies, quick couplers, valves, hoses, fittings, pneumatic cylinders and thread sealants. Most leaks occur at points of use, so begin your search there.

How to Find Leaks

Locating air leaks in a loud factory floor is next to impossible with a human ear. The best, and easiest, way to find air leaks is using ultrasound. Ultrasound detectors allow you to hear the minute hissing noise produced by leaks, despite the roaring noise of a production area. Ultrasound detectors are portable, easy to use and require little training to get started.

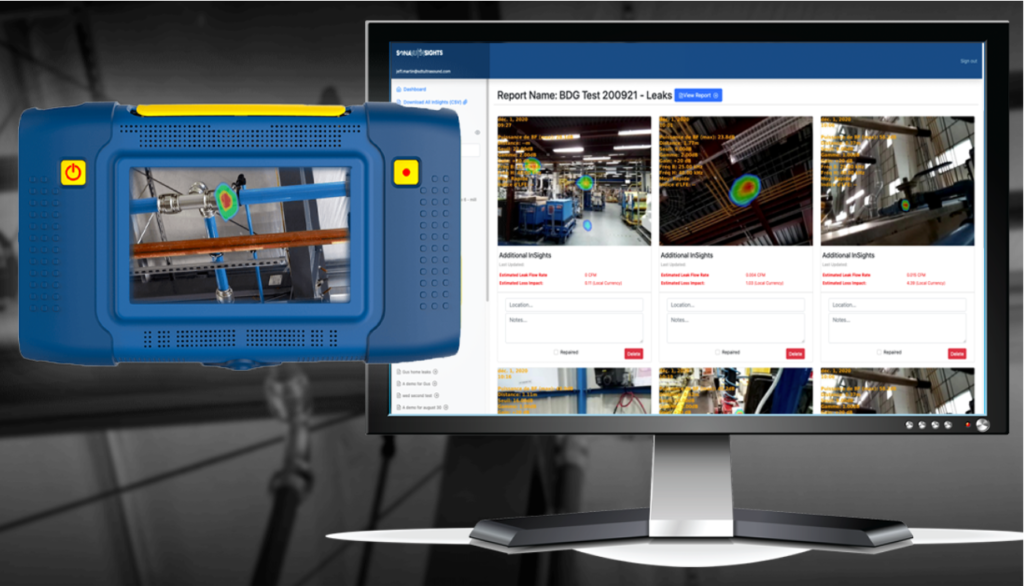

SDT have a range of hand-held devices from the entry level LEAKChecker to the SDT340 which can be used for both airborne & structure-borne applications. And now with the all new SonaVu acoustic imaging camera you can ‘SEE” the leak in real time making it even easier to scan larger areas.

Photo (L-R) – LEAKChecker, SDT340, SonaVu Acoustic Camera

How to Manage Leaks

It’s not enough to just find leaks. Fixing and documenting savings is a necessary part of the program.

Fortunately SDT have simple and easy to use platforms to track and calculate these costs.

A mobile smartphone App available for iOS and Android. LEAKReporter is focused, simple and free. It saves inspectors time and money by documenting leaks in pictures, estimating their cost impact and creating fast comprehensive leak reports. This can be used with the LEAKChecker, SDT200, SDT270 or SDT340.

Is a web application for creating instant reports of compressed air leak and electrical asset surveys performed with the SonaVu Acoustic Imaging Camera from SDT. Document findings, prioritize repairs, estimate cost impact, eliminate energy waste, and save money with this free application.

Being competitive has never been more important than it is today. Energy costs directly impact your bottom line. There is no easier way to reduce energy waste than to tackle the “low hanging fruit” in your compressed air system.

It doesn’t have to be complicated.

Detect, fix and save money with SDT Ultrasound Solutions.

Author – Tristan Rienstra